All photos are used with the permission of Rogue Fitness

Design Challenge: Design, prototype, and release a 20” and 40” lat pull down bar by the end of the internship using up excess stainless steel.

Design Constraints: Must incorporate excess steel, follow branding guidelines, must attach to the Monster Lat Pulldown Machine.

Final Deliverables: A viable and developed product, product page, SKUs, product cost, engineering drawing, gauging pages, bar gauges.

Software: Autodesk Inventor

Time frame: 3 months

Supervisor: Ahmik Jones, Head of Product Development

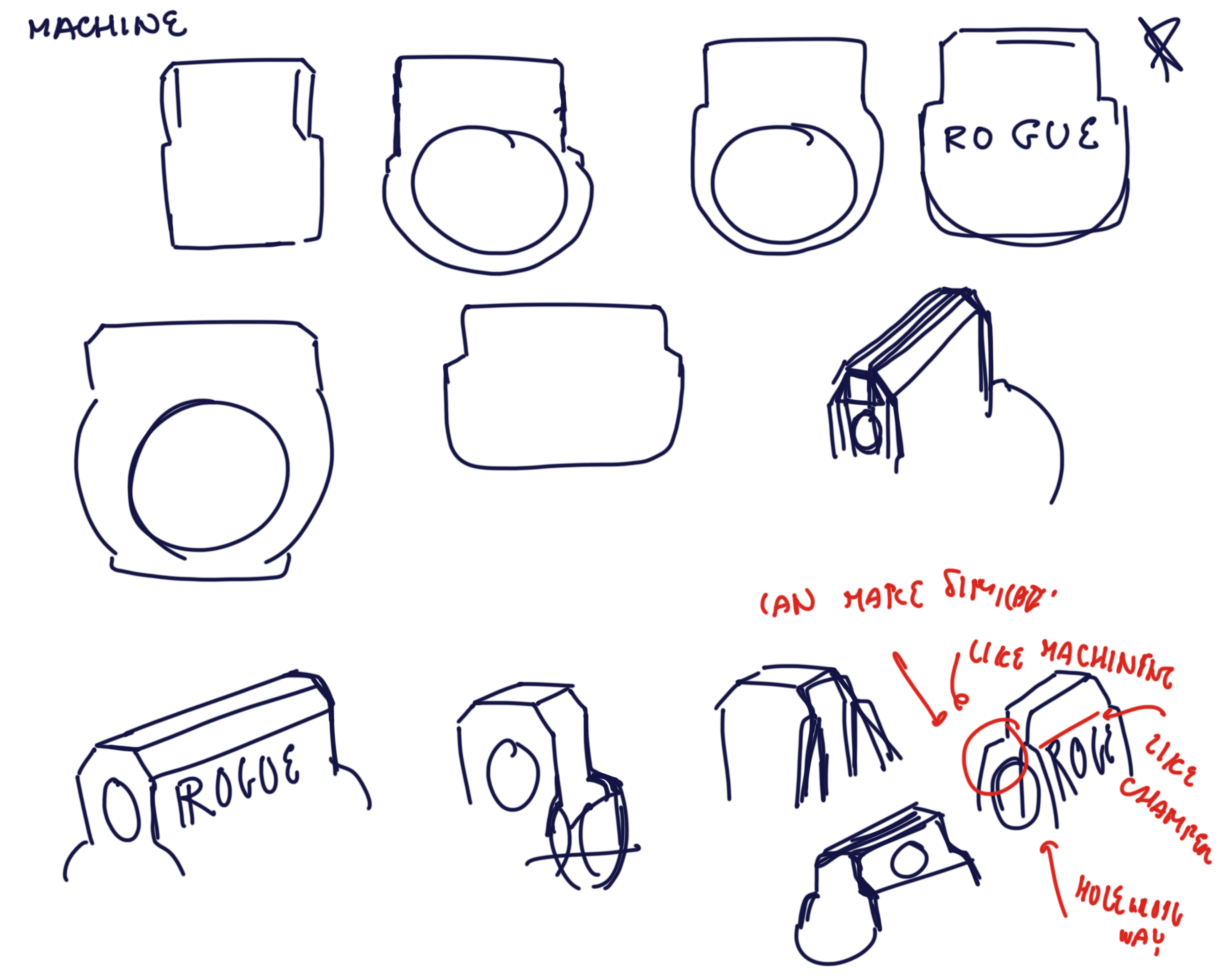

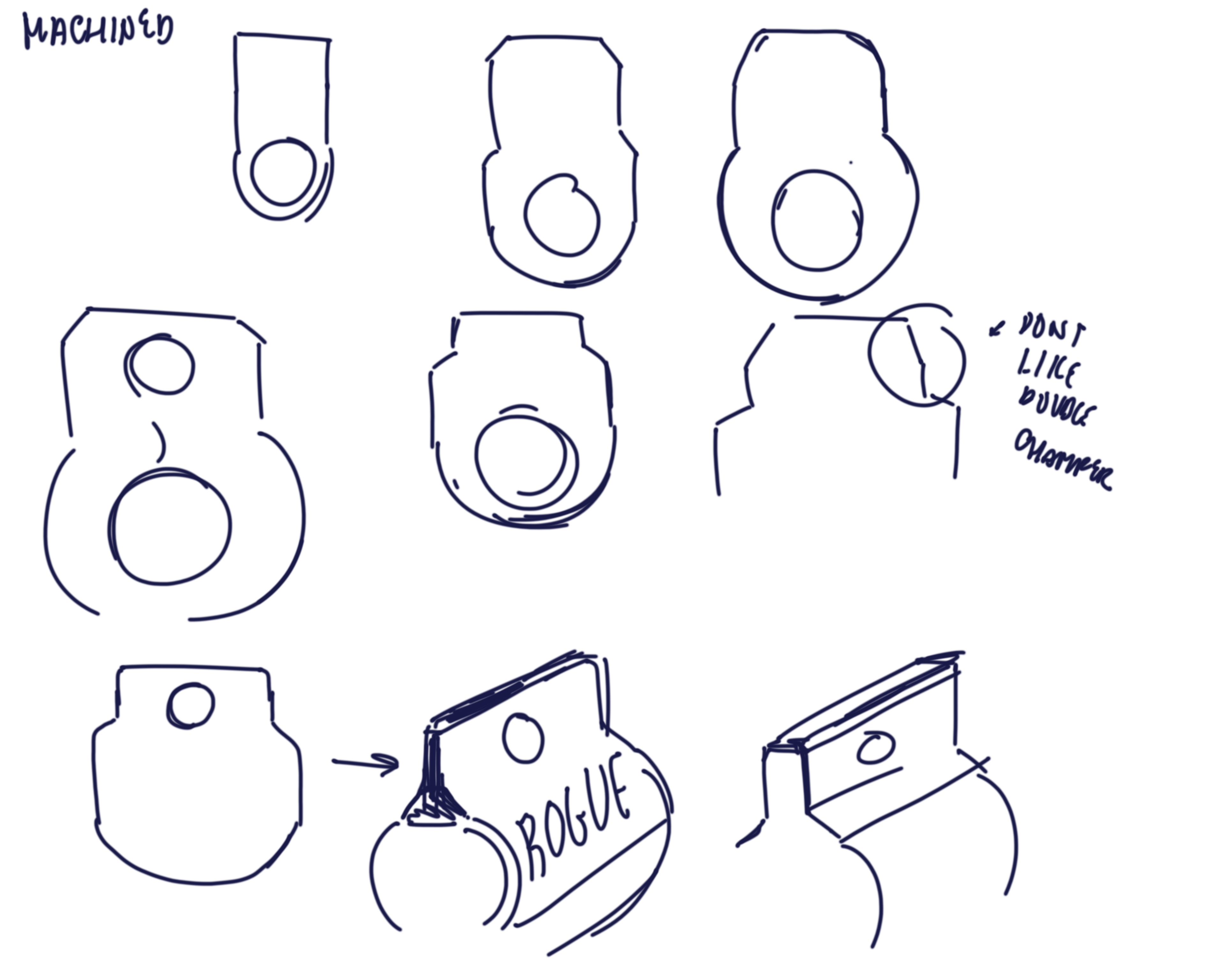

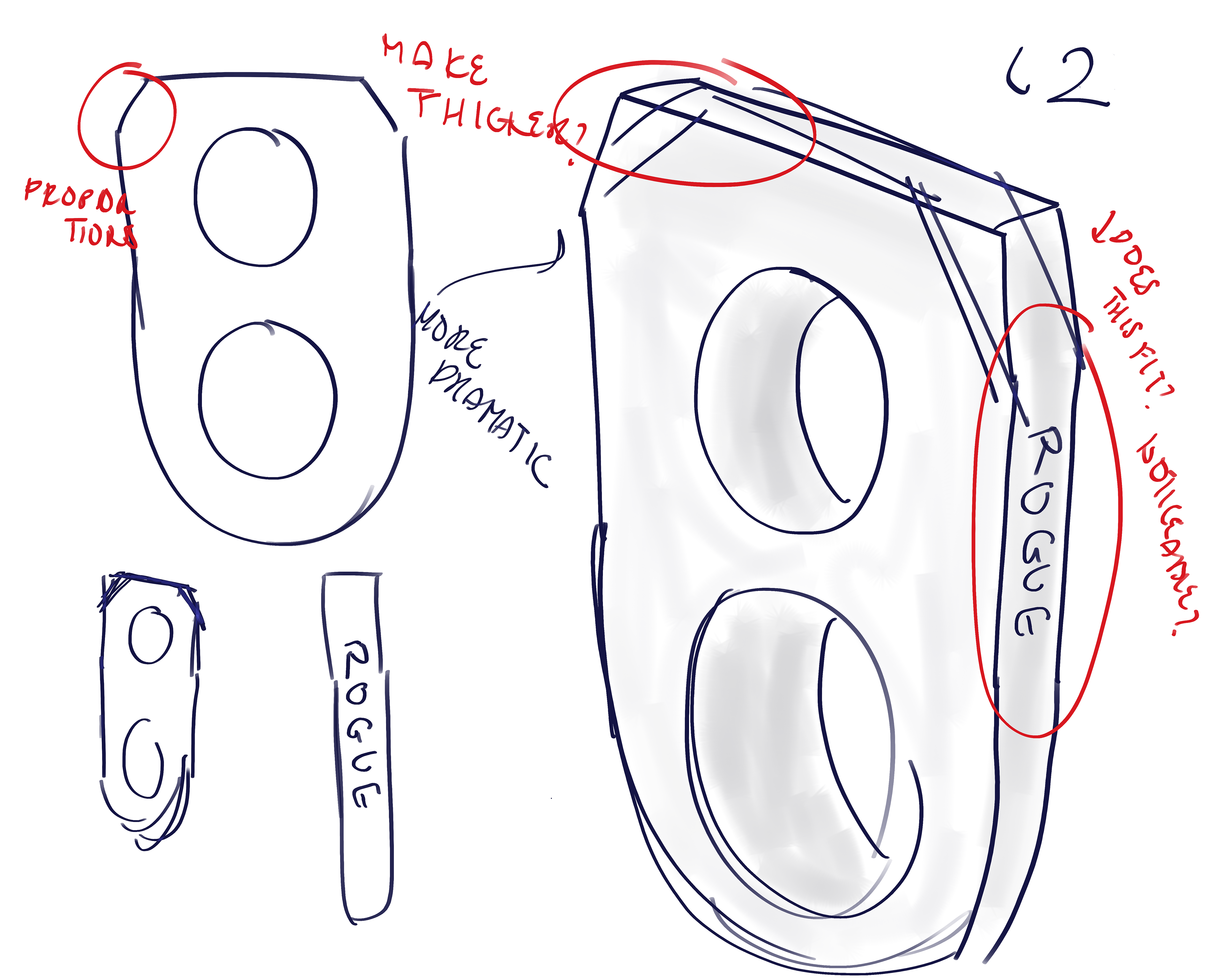

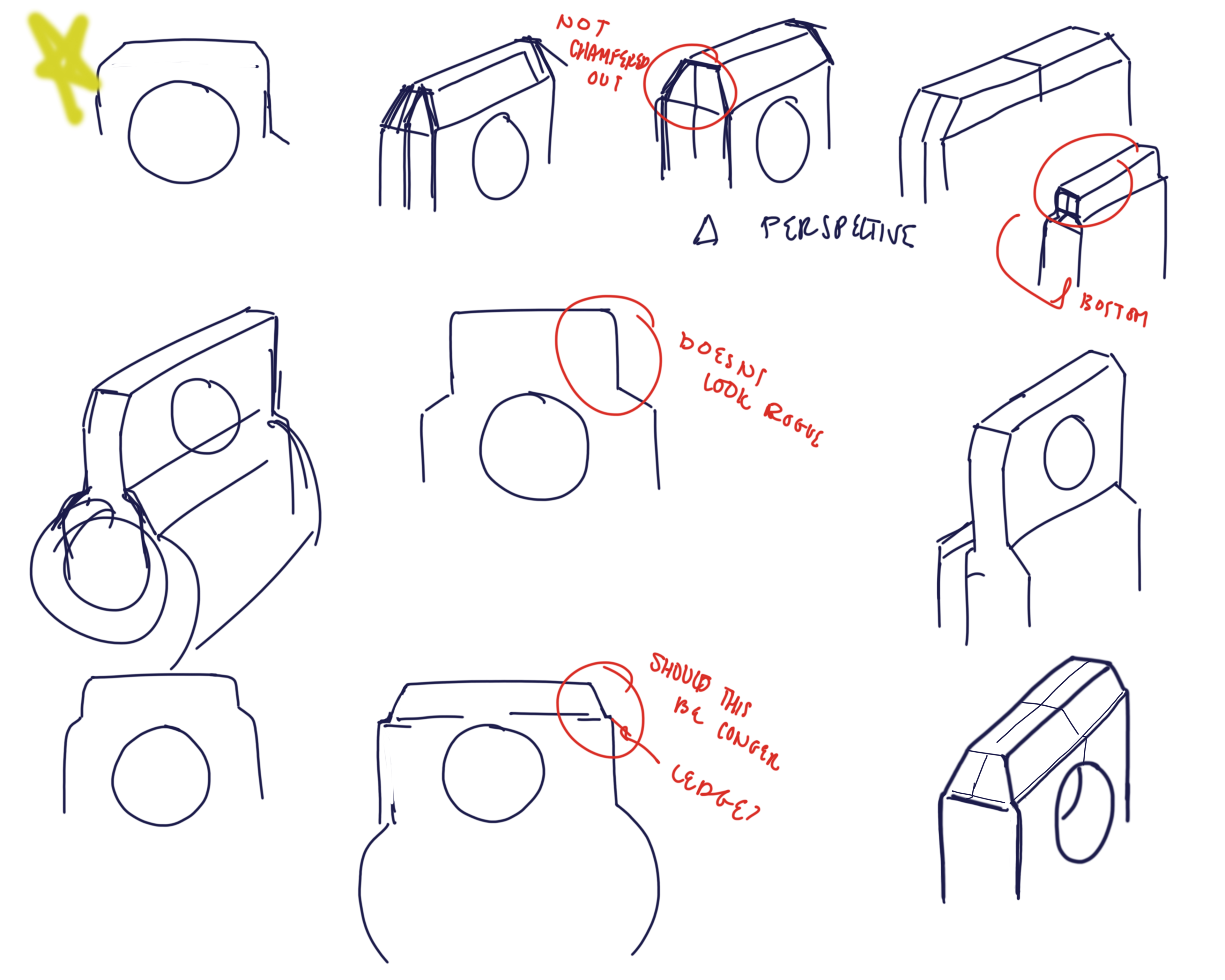

Swivel Iterations

I had to develop and prototype two different swivels: one that was lasered and one that was machined. While I modeled the prototypes on Autodesk Inventor, the machinists at Rogue prototyped the swivels. We determined that creating a machined swivel would be too expensive so I went forward with the lasered version. I also had to make sure that the swivel fell in line with Rogue's brand identity.

Prototypes

I prototyped different sizes of the swivel.

Comparing size and form of the prototypes and making sure that the shaft collar aligned exactly with the edges of the swivel.

Swivel attached to the carabiner

Added a set screw hole to fasten the set screws. In addition, this helped with assembly time and accuracy of the shaft collar placement.

Decided between steel and zinc set screws.

Final 20" straight lat bar prototype.

Final Packaging

I had to determine the assembly time of this product by boxing up the product four separate times. This included assembling the box, assembling the product, adding foam for protection, then taping and securing the box.

Making sure the product fits in the box.

Product packaged.